Improvement cases

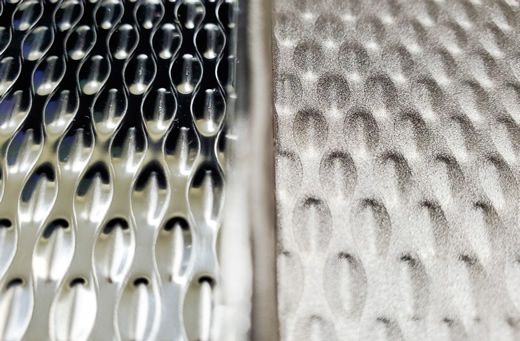

CASE 01Short time breakdown in the productivity line at pouch distribution device

Customer issues

The food product machine gets caught at the shooter part, because the pouch is not slippery.

Proposed processing

Results・Effect

As a result of giving the shooter slipperiness, the frequency of production-line stops have decreased.

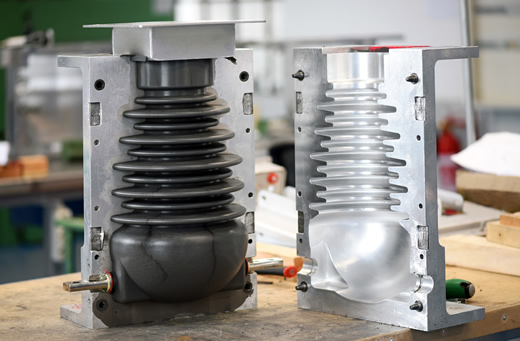

CASE 02Improved life of GFRP molding dies

Customer issues

Copper alloy molds have low hardness and corrosion resistance.

Proposed processing

Results・Effect

As a result of providing hardness and corrosion resistance, mold life improved thousands of shots to over 600000 shots.

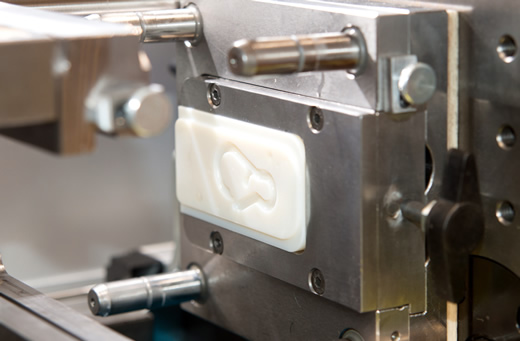

CASE 03Improved wear resistance of complex injection molding dies

Customer issues

Copper alloy molds have low hardness and corrosion resistance.

Proposed processing

Results・Effect

Mold life improved from 3500 shots to 25000 shots, by providing a coating film with uniform thickness capable of covering complicated (complex) shapes.

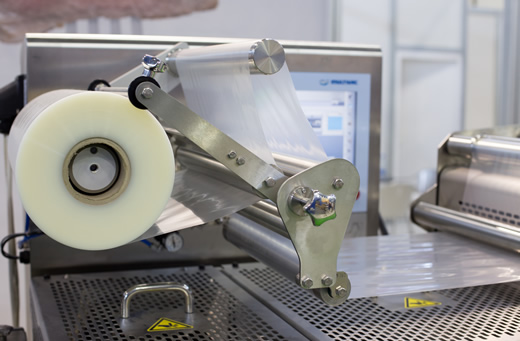

CASE 04Prevented adhesion of film and inks residue on the die roll

Customer issues

It takes a long time and effort to remove the glue and inks adhering to the die roll.

Proposed processing

Results・Effect

As a result of providing non-adhesiveness, the cleaning cycle of the roller was improved from 3000m cycle to 5000m cycle.

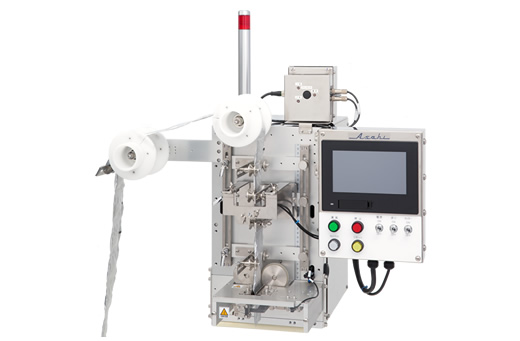

CASE 05Achieved injection molding that doesn't use a mole release agent

Customer issues

Urethane foam moldings requires a mold release agent and a lot of time, because it is difficult to release.

Proposed processing

Results・Effect

The effect of eliminating the need for a mold release agent was obtained, and the frequency of mold cleaning such as the mold release agent could be reduced.

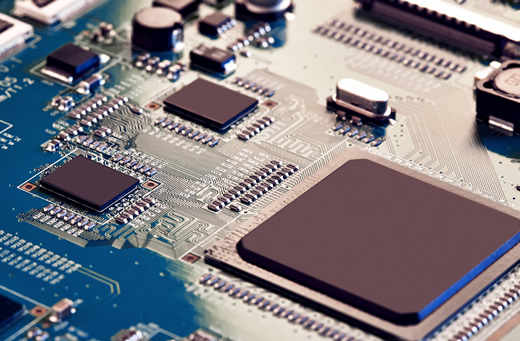

CASE 06Black coating that doesn't fade under UV light

Customer issues

The black alumite applied around UV exposure equipment used in semiconductor manufacturing process fades due to aging degradation and can't exhibit prolonged its performance.

Proposed processing

Results・Effect

Electroless black Ni plating (PHOSBLACKⅢ) is an inorganic substance, that does not change color under high-power UV light.

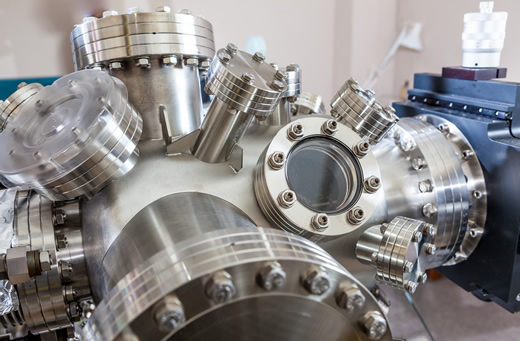

CASE 07Black coating applicable to vacuum equipment

Customer issues

Dry coating is generally used as a part in vacuum equipment, but it doesn't have high light absorption.

Proposed processing

Results・Effect

Black coating (SOLBLACK) has the highest light absorption rate among general plating, and has reduced the amount of outgas to less than 1/10 of general plating.

CASE 08Be-Cu (Beryllium Copper) products plating and reprocessing

Customer issues

Be-Cu (Beryllium Copper)is classified as a difficult to plate and reprocess material, molds need to be remade frequently as they are difficult to plate and often cannot be reprocessed.

Proposed processing

Results・Effect

Copper alloy molds can be used repeatedly as they can be removed and replated multiple times.

CASE 09Prevented adhesion of films by static electricity

Customer issues

Static electricity is generated when the film slides.

Proposed processing

Results・Effect

Static electricity can be released because of plating and fluororesin composite layer encouraging conductivity.