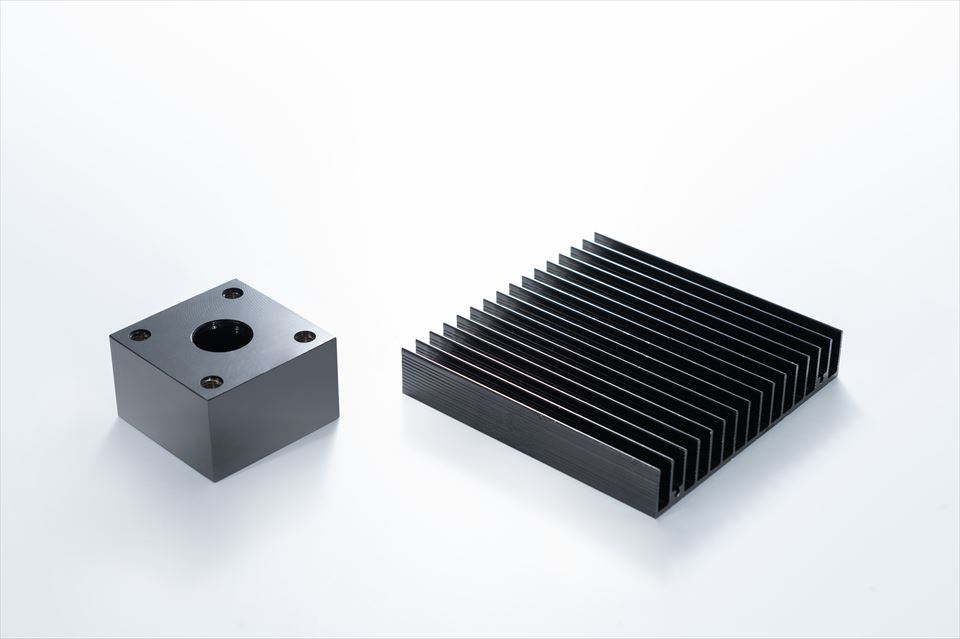

PhosblackⅢPRODUCT INFORMATION

Scratch-resistant black electroless plating that can be applied to complex shapes

Functions / characteristics

Processable size(mm)

350×800×800

Processable materials

Iron, Stainless, Copper alloy, Aluminum alloy, etc.

Characteristics

- Glossy black electroless plating.

- Excellent heat and light resistance.

- Harder and scratch-resistant is better than other black coatings.

- It has a uniform coating even so complicated shape.

- No environmentally regulated substances such as chromium and lead are used.

Characteristics

| Light absorption | Absorbs about 90% of the light in the visible light range (380-750 nm) on average. |

|---|---|

| Heat resistance | Even after being held at 300°C for 2 hours, the reflectance does not changes much. |

| Accuracy | It has a uniform coating even so complicated shape. |

| Materials | A variety of materials can be treated. Please contact us for details. |

TEST DATA

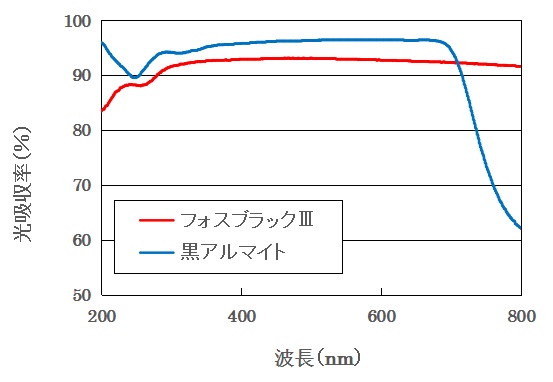

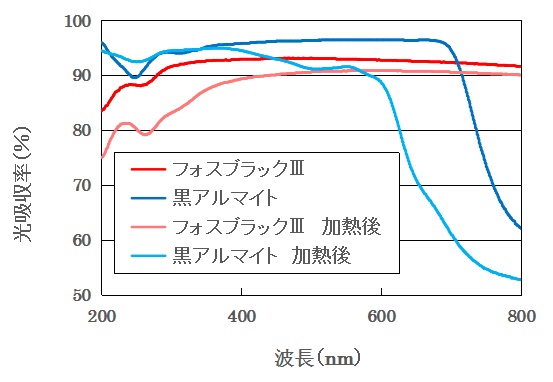

Light absorption

Test method

An integrating sphere was attached to a spectrophotometer to measure the total light absorption.

Equipment used: Hitachi High-Tech U-3900 with 150mm diameter integrating sphere

Measurement range: 200 to 800 nm

Measurement light source: D2 lamp (200 to 340 nm), tungsten lamp (340 to 800 nm)

Result

PhosblackIII absorbed 91% of the light in the visible light range.

Heat resistance

Test method

PhosbrackIII and black anodized aluminum were heated at 300℃ for 2 hours, and the light absorption in the visible range before and after heating was compared.

Equipment used: Hitachi High-Tech U-3900 with 150mm diameter integrating sphere

Measurement range: 200 to 800 nm

Measurement light source: D2 lamp (200 to 340 nm), tungsten lamp (340 to 800 nm)

Result

PhosblackⅢ

Before heating : 91% → After heating : 90% ⇒ 1% lower

Black alumite (Black anodized aluminum)

Before heating : 91% → After heating : 78% ⇒ 13% lower

The light absorption rate of black alumina decreased by about 13%, on the other hand PhosblackⅢdecreased by about 1%.

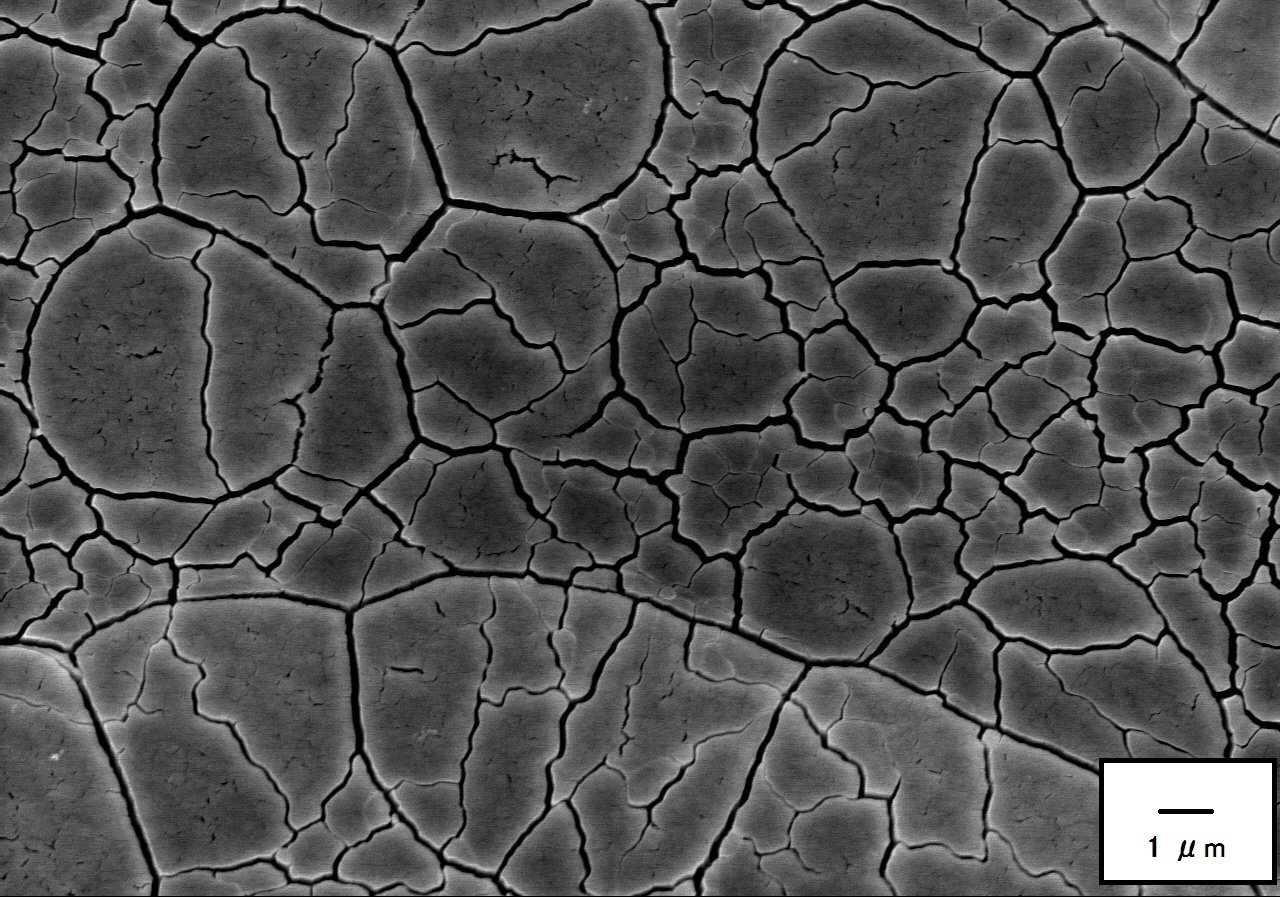

Surface observation

Test method

The surface of PhosblackⅢ was observed by SEM.

Equipment used: JEOL S-4800

Result

Cracks of various sizes were observed on the surface.

(Crack width: 50 to 200 nm)