SolblackPRODUCT INFORMATION

The optical confinement effect of the nano-sized three-dimensional structure achieves high light absorption.

Functions / characteristics

Processable size(mm)

350×800×800

Characteristics

- The optical confinement effect of the nano-sized structure achieves high light absorption.

- Matte black does not almost reflect light.

- It is little outbreak of the outgas, ideal for use in a vacuum.

- Corrosion resistance is better than electroless nickel plating.

- Heat collecting property is higher than blackbody coating.

- Excellent heat and light resistance.

- It has a uniform coating even so complicated shape.

- No environmentally regulated substances such as chromium and lead are used.

※Due to the special film structure, the plating film peels off easily, making it unsuitable for friction environments.

Characteristics

| Light absorption | Absorbs about 98% of the light in the visible light range (380-750 nm) on average. |

|---|---|

| Low reflection | Regular reflectance of visible light at 12° angle of incidence is 0.2%. |

| Use in vacuum | Rate of outgassing is about one order of magnitude lower than PhosblackⅢ. |

| Corrosion resistance | Corrosion resistance to artificial acid rain is better than electroless nickel plating. |

| Heat resistance | Even after being held at 200°C for 2 hours, the reflectance does not changes. |

| Accuracy | It has a uniform coating even so complicated shape. |

| Materials | A variety of materials can be treated. Please contact us for details. |

Purpose

Gravitational Wave Telescope(KAGRA), Antireflection and stray light applications for optical telescopes

TEST DATA

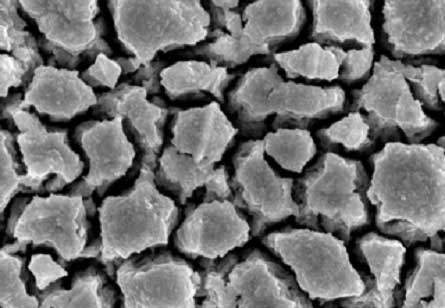

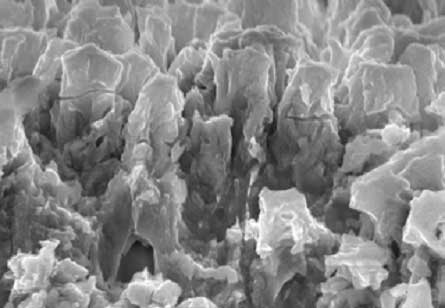

Surface observation

Test method

The surface of Solblack was observed by SEM.

Equipment used: JEOL S-4800

Result

Solblack was observed to have a three-dimensional structure of creeks.

Surface

Observation at KINDAI UNIVERSITY center for collaborative research.

Cross section

Observation at KINDAI UNIVERSITY center for collaborative research.

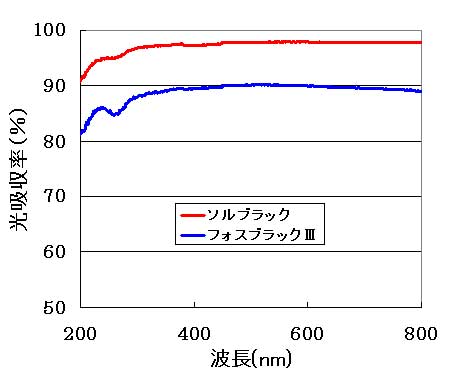

Light absorption

Test method

An integrating sphere was attached to a spectrophotometer to measure the total light absorption.

Equipment used: Hitachi High-Tech U-3900 with 150mm diameter integrating sphere

Measurement range: 200 to 800 nm

Measurement light source: D2 lamp (200 to 340 nm), tungsten lamp (340 to 800 nm)

Result

Solblack absorbed 98% of the light in the visible light range.

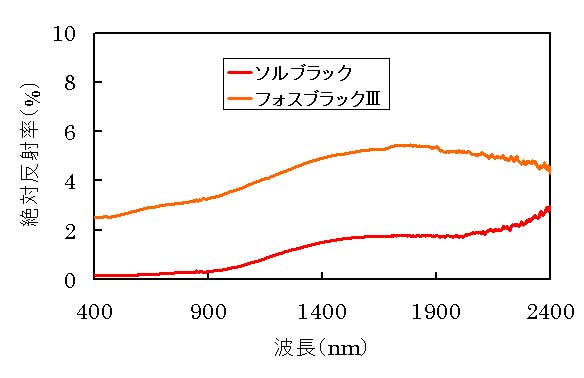

Reflection

Test method

An absolute reflectance measurement device was attached to a spectrophotometer to measure the reflection.

Equipment used: Shimadzu Solidspec370

Measurement range: 400 to 2800 nm

Light incidence angle: 12°

Result

The regular reflectance of Solblack was less than 3% in all measurement areas, and especially less than about 0.2% in the visible area.

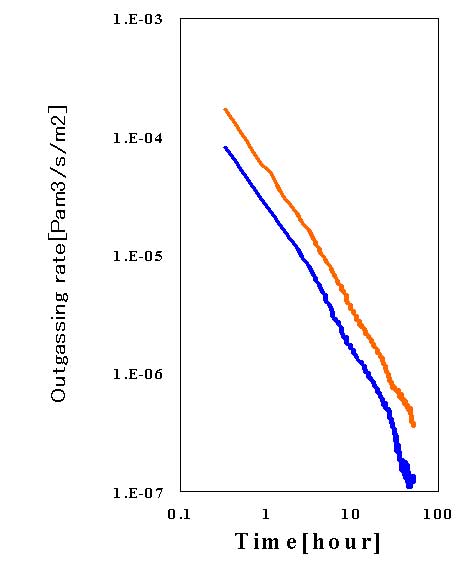

Vacuum characteristics

Test method

The gas release rate from the plated surface was measured by conductance modulation method.

Result

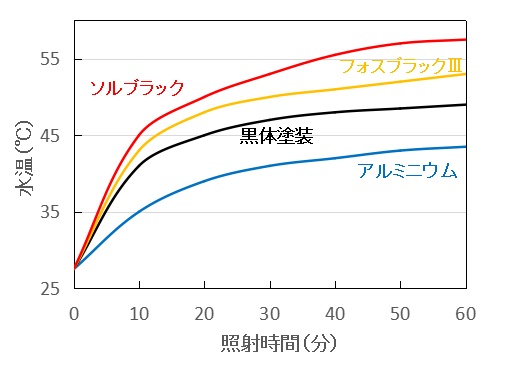

Heat collecting

Test method

The surface-treated aluminum pipe was irradiated with light, and the fluctuations in the internal water temperature

were recorded.

Amount of water: 8 mL

Light source: 50W bulb

Distance from light source: 10 cm

Result

集熱性のグラフ

Heat resistance

Test method

The test piece was held at 200°C for 2 hours, and the average total reflectance in the visible region before and after the test was compared.

Result

Even after being held at 200℃ for 2 hours, the reflectance does not changes.

| 平均反射率 | |

| Before heat treatment | 2.5 % |

| After heat treatment | 2.5 % |